Barrel polishing is a dry treatment process that achieves a mirror-polished finish on numerous plastic and natural material pieces (mother of pearl, horn,…). The process involves placing the pieces to be polished in rotating barrels containing small wooden sticks coated beforehand with our specially formulated abrasive pastes. With over 60 years of experience in this field, TCN offers a comprehensive dry polishing process and supports you in implementing your own process. Following our R&D team’s work, we recently formulated our dry polishing process with eco-friendly polishing pastes.

Multiple successive polishing steps with the appropriate polishing paste eliminate surface defects from the pieces (mold lines, scratches,…) to achieve satin or glossy finishes. Moreover, we formulate, manufacture in France, and globally distribute a range of polishing pastes with varied grit sizes for a complete process: deburring, sanding, semi-sanding, polishing, and finishing.

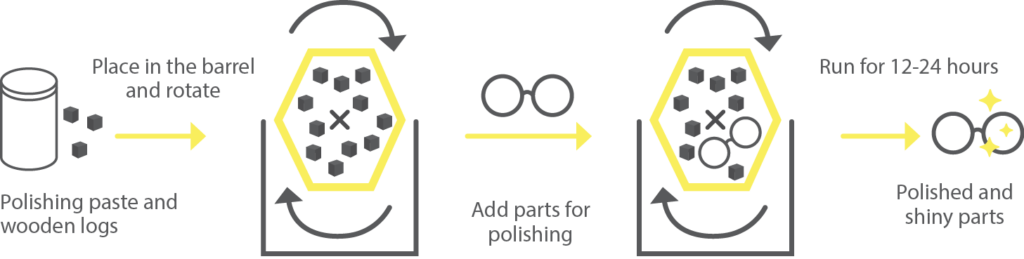

Discover the ease of use and effectiveness of our processes through the diagram and videos below.

For the initial deburring step, you have two options:

Cellulose acetate, cellulose-derived bioplastic

Metal bucket of 20 kg

Eco C600 and 2896C600 sanding pastes contain moderately abrasive powder suitable for a second sanding to smooth acetate pieces in preparation for fine sanding. Our brand-new EcoC600 smoothing paste contains no classified substances, is environmentally friendly, and is manufactured using vegetable-derived solvents.

Cellulose acetate, cellulose-derived bioplastic, polyester, plexiglass®, and precious metal

Metal bucket of 20 kg

Polishing paste 605AN or Eco C605 contains fine abrasive powder for achieving glossy finishes on various materials. It is particularly used in the third step of polishing acetate. Recommended for high-quality finishes and pieces to be dyed subsequently.

Base 605 prepares the adherence of paste on wooden sticks.

Cellulose acetate, cellulose-derived bioplastic

Mirror-polished finish

605 AN paste, metal bucket of 20 kg

Base 605, metal bucket of 12 kg

Eco 605+ polishing paste and Eco 605 base are the eco-friendly versions of polishing paste 605AN and base 605. Formulated in our laboratory with bio-solvents to meet the needs of clients committed to eco-responsibility.

Cellulose acetate, cellulose-derived bioplastic

Mirror-polished finish

Eco C605, metal bucket of 20 kg,

Eco 605 base, metal bucket of 12 kg.

Eco BS3208 finishing paste contains self-polishing waxes that achieve a perfect finish after polishing or dyeing operations.

Cellulose acetate, cellulose-derived bioplastic, polyester, plexiglass®, and precious metal

Metal bucket of 12 kg