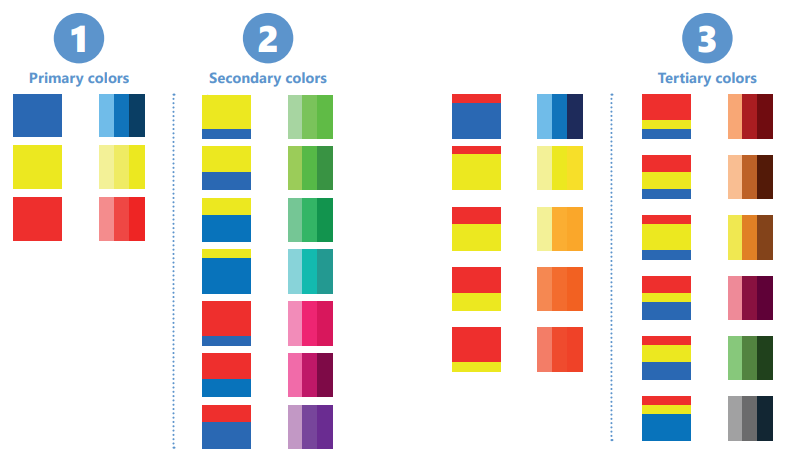

If you have the intention of creating your own color, you will have to choose criteria adapted to the realization of the desired shade after defining the color that you need (see part 3), starting from selecting primary colors that will be used to produce it.

4.1. Choice of primary colors

In practice, TCN can offer more than the 3 basic colors of blue, yellow and red to achieve the wide color panel that its customers need. The mixture of colors systematically causes a loss of the vivacity of the final shade. We have to adapt our methods to overcome this problem.

Therefore, depending on the desired color, we will have to work with intermediate colors as lemon and golden yellow, pure orange, pink, fuchsia, scarlet and red, purple, royal blue, turquoise or green in order to reach bright colors.

You can also make your own shades through our dyeing products. Our range of dyeing products includes essential basic colors to get bright tones and combine them. The wide range allow to easily get tertiary colors.

4.2. Dyeing conditions

Our products offer an easy-to-use dyeing process which consists in dipping your plastic parts in a coloration bath. You will have to use this process if for instance you want to color CR-39® organic lenses with our CRX powders. You can dye your parts from a large number of plastic types, such as polyamide (TPU, PA12, PA11, PEEK…), polyurethane, PMMA, ABS…

This process is suitable for many application fields since a brief dipping for a few minutes is sufficient. The final color depends on many parameters: the nature of the plastic material, the initial color of the substrate, its aging, the dyeing conditions (dilution, temperature…), the lifetime of the dyeing baths… These factors can be modified according to the result that you want to get.

Moreover, our coloring products do not distort the appearance of your objects:

- transparent objects stay as they are through a transparent colored result,

- if you have white or opaque objects, you will obtain an even result and with nacred objects, a nacred-colored result.

4.3. Building of the dyeing bath

Knowing the ratio of basic colors of the dyeing bath is helpful in order to potentially do a subsequent correction. As it has been said before, it is possible to obtain different colors according to the quantity of every primary color in a mixing. For instance, you can make a mix of several basic colors by diluting them in water when using GTC dyes, to create a new one.

The illustration below will help you to have an idea of the type of dyes that you can get by mixing different basic colors in varied quantities. Then it is up to you to adapt the use of the products depending on the dyes that you are looking for: more or less bright, light, dark…

4.4. Correction of the color

When you issue your plastic part from the dyeing bath, it is possible that the final color result is not exactly the one that you expected. In this case, corrections can be made directly in the dyeing bath or by dipping your part in an additional correcting dyeing bath.

By the effect of the complementary colors (see parts 2 and 3), the addition of approximately 10% of the missing complementary color makes it possible the small rectification of the color, perceptible to the eye.

If the final shade is too strong, add the opposite color:

Add orange if it is too blue, violet if it is too yellow and green if it is too red.

If the color is too light, increase:

- the dyeing time,

- the concentration of dyeing product,

- the dyeing temperature,

Or add some specific carrier.

If it is too dark, reduce:

- the dyeing time,

- the concentration of the dyeing product.

If the result is too dull, select brighter colors from our range of basic colors.

If you prefer to entirely redo your color, TCN can provide a decolorant to remove the shades that do not suit you, regardless of which dyeing products you choose.